NEWS

News from our daily work, innovation, cooperation – read here worth mentioning from GLY

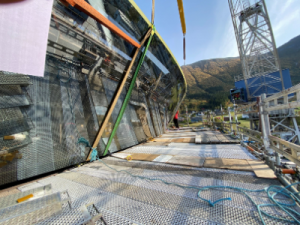

Installation team completed the glazing of the observation lounge on REV

Our team completed the glazing of the observation lounge on deck 9 in October 2020. In addition to 32 straight and curved panes, the curved front pane with a dimension of 11.2 x 2.8 meters and a weight of 4.5 tons is the crowning glory of the glazing of the observation area, which is 27 meters above the waterline. The panes were installed tied to the ship structure (frameless design) with the invisible mechanical fastening system GLY-EdgeLock® developed by GL Yachtverglasung.

Technical details:

glazing

Total glass area: 240 qm

Number of glass panels: 33 pieces (30 flat, 3 curved)

high performance insulated glass units (IGU)

front window:

dimensions: 11,2×2,8 meters

area: 32 qm

weight: 4,5 tons

geometry: curved (Radius ca. 23 meters)

Milestone: GLY installed pool glass

Our highly qualified installation team has reached another milestone. The pool floor was successfully installed on a new building project this week.

dimensions:

12×2 meters

5.900 kg weight

M/Y ARTEFACT has been shortlisted for the International Yacht & Aviation Awards 2020

These awards are presented by the leading magazines Design et al and Luxe et al.

The online voting is ongoing and will remain open until 4.09.2020.

The voting process is simple:

- Take 5 minutes of your time

- Click on the voting link and follow the instructions

- Note: everyone may vote only once. Duplicate votes will be removed.

WTSH promotes trade fair participation at SMM 2021 in Hamburg

GL Yachtverglasung GmbH will be on site as an exhibitor at SMM from February 2-5, 2021. We present our unique services and innovations at the leading international trade fair for the maritime industry.

Milestone at REV-project: GLY installed main bridge window

Our highly qualified installation team has reached another milestone in the REV project. The main bridge window of the explorer yacht was successfully installed this week.

weight: 1.300 kg

tickness: 34 mm

wide: 7 meter

high: 2 meter

Everyone is talking about GLY – Wirtschaftsland 2020

“Megayachts, crusaders, luxury ships. Their owners and shipping companies can hardly get past Halstenbek in Schleswig-Holstein. This is where GL Yachtvergalsung is located. And thus the absolute expert for everything that ensures true vision at sea …”

The new glass mounting device in use now

In the course of a project execution the GL Yachtverglasung GmbH has put the largest, automotive glass mounting device into operation.The fitting machine is an inhouse-development, which was formed in cooperation with a specialized mechanical engineering company. It does justice to the constantly increasing claim on the glass fitting in the superyacht sector.

The new glass mounting device can be individually adapted to pane size, weight and local conditions. It enables GL Yachtverglasung to install glass in sizes ranging from 2.5 to 12 metres in length and weighing up to 5.5 tons. The installation positions can be vertical or may be inclined up to 15 degrees. Due to the special design, the minimum track width is 1 metre and can be used in areas that cannot be reached with cranes, such as under deck overhangs. The mobile mounting device itself is demountable and stowed in standard containers. This allows an international use.

Latest development in the fire protection glazing

One of the latest development is the glazing of fire-resistant windows with the highest fire resistance class A60. After extensive testing we can now present our product GLY-MarineCobondFR60®.

Due to the special construction of the glass, a flush-mounted integration neither with visible, mechanical fastenings nor with attachment frames is possible.

After completion of the certification process, GLY-MarineCobondFR60® can be ordered with a width of over 4 metres and a height of 2 metres. With a total thickness of less than 6 centimetres, the fire-resistant glass meets the A60 requirements of the IMO 2010 FTP Code.

GLY is offical listed as supplier for REV

REV is the largest exploration yacht ever built! GLY is assigned in development, design, delivery and installation of 1.800 qm exterior glazing.

Adhäsion: DIN2304 – The financial effort is worthwhile

At the beginning of 2016 an adhesive quality control campaign was started with DIN 2304-1. GL Yachtverglasung GmbH has now become the first company to be certified according to this new standard. The editorial team talked to the director Lars Engel about the motivation and the background. => Read the whole interview.

Glass for the largest yacht is comming from Halstenbek

The owner managed company GL equiped trains and ships with special glazing. Special requests from billionaires are gladly fulfilled. => please read here the total article.

DIN 2304 – quality management in the adhesive technology – GL Yachtverglasung is the first company worldwide which is certified

Innovation and quality management within our working processes and results is of highest relevance for us. In regards to this we already implemented the auditing procedure of our gluing processes after DIN 2304. DIN 2304 is requested by industry and craft. On December 8th, 2016 the working processes of GL Yachtverglasung had been successfully certified by Fraunhofer Institute.

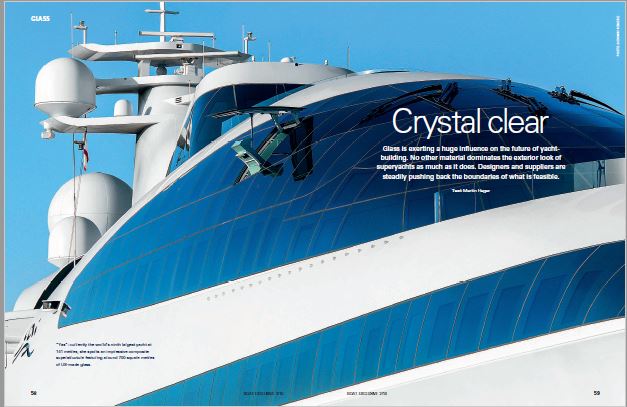

Boote Exklusiv: A german article about the influence of glass in modern yachtbuilding”

Glass influences the future of yacht building massively. Hardly any material dominates so much the Exterior look modern large formats. Designer and supplier move continuously the limits of feasibility.

A sailing yacht redefines the boundaries of design and technology

The futuristic sailing yacht A is with 143 meters longer than the largest windjammer in the world.

Boote Exklusiv: A german article about sailingyacht “A”

The motor yacht with sail-support has 142.81-meter and three masts that protrude 100, 93 and 92 meters into the sky and carry 4,500 square canvas.

OnBoard Magazine: The clear advantage

Andreas Schipper looks at the evolution of using glass within superyacht design and construction and asks, what does the future hold?

Lloyds intern: GLY gets the Type Approval for GLY-MarineCobond®

On Monday 10 March, a hand over ceremony for a Type Approval Certificate took place at Lloyd’s Register’s 71 Fenchurch Street for the German mega yacht supplier GL-Yachtverglasung.

Inside Marine: GL Yachtverglasung

Family-owned GL Yachtverglasung GmbH is part of a company with more than 100 years of experience in work with glass.